Product Introduction

1. Product Features

• High-Density Storage, Space-Saving:Forklifts can drive directly into the rack, reducing the number of aisles and increasing warehouse space utilization.Storage density is 50%-80% higher than conventional pallet racking systems, ideal for large-volume storage needs.

• First In, Last Out (LIFO) or First In, First Out (FIFO) Operation:The racking supports LIFO (Last In, First Out), suitable for long-term storage or goods with less frequent turnover.It can also be designed for FIFO (First In, First Out), ideal for products with expiration dates or freshness requirements, such as food, beverages, and cold chain storage.

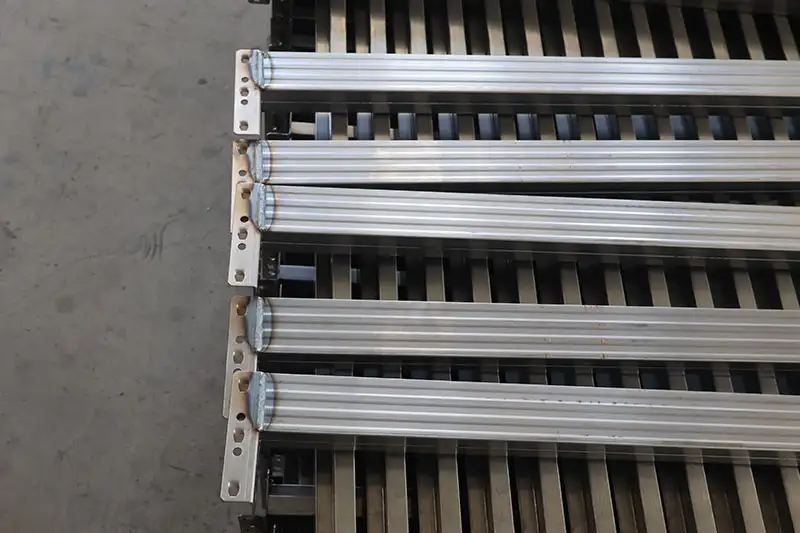

• Stable Structure with High Load Capacity:Made of high-strength cold-rolled steel, ensuring long-term stability and durability.Equipped with rails, pallet support beams, and anti-collision barriers, enhancing the safety and durability of the rack.

• Suitable for Large-Volume, Low-Variety Storage:Perfect for industries with a low number of SKUs (Stock Keeping Units) but large storage volumes, such as food, beverages, dairy products, chemicals, and tobacco.Ideal for cold storage facilities, reducing aisle space in cold storage environments and improving refrigeration efficiency.

• Compatible with Standard Pallets and Forklifts:Compatible with standard pallet sizes (1200×1000mm / 1200×800mm, etc.).Works with front-loading forklifts, counterbalance forklifts, cold-storage forklifts, and other equipment for smooth storage and retrieval operations.

2.Product Advantages:

• High Storage Density – Increases warehouse capacity by 50%-80%.

• Reduces Aisle Space – Forklifts can drive directly into the racking system, minimizing aisle requirements.

• Strong and Durable Structure – Built with high-strength steel for long-lasting use.

• Ideal for Cold Storage – Reduces cold storage aisle space, improving refrigeration efficiency.

• Supports FIFO / LIFO – Flexible storage options to meet various goods management needs.

3.Applications:

• Food & Beverage Industry – Ideal for storing large quantities of food, beverages, dairy products, and other perishables, especially in cold storage.

• Chemical & Pharmaceutical Industry – Suitable for storing bulk chemicals, pharmaceutical products, and other industrial goods.

• Tobacco & Alcohol Storage – Perfect for storing large volumes of tobacco, cigarettes, alcohol, etc.

• Manufacturing & Distribution Warehouses – Useful for parts, raw materials, and finished goods storage, improving warehouse turnover.

Item | Specification |

Upright Height | 2000m - 12000m (Customizable) |

Beam Length | 1200mm - 4000mm |

Rack Depth | 800mm - 1500mm |

Load Capacity per Shelf | 1000kg - 5000kg (Depending on material and design) |

Color | Blue, Gray, Orange, etc. (Customizable) |

Material | Cold-rolled steel (Q235B), electrostatic powder coating |

Versatility | Suitable for storing various items such as tools, equipment, files, etc. |

OEM Support | Option available for OEM (Original Equipment Manufacturer) support |

Drive-through shelves

Category:

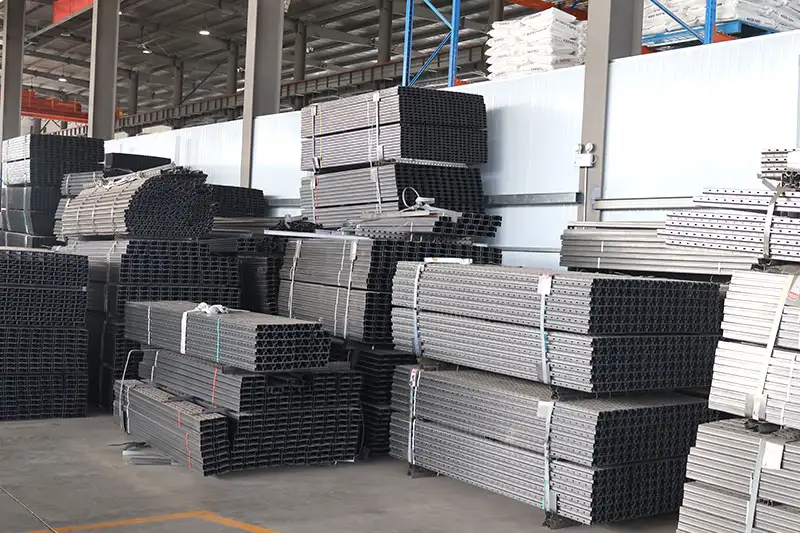

Warehouse Photos

Key Advantages

ONE-STOP SOLUTION

2D/3D design, manufacturing, delivery, installation, commissioning, and after-sales—with custom OEM/ODM capability.

HIGH-QUALITY STANDARDS

Uses cold‑rolled steel, precision manufacturing, and rigorous QC to meet multiple international standards.

SERVICE

Good Pre-sale、on sale and after sales service.

ROBUST R&D

Continuously innovating product lines, supporting custom sizes/materials per client requirement.

GLOBAL DELIVERY

Export track record spans Southeast Asia, South America, Africa, servicing supermarket and warehousing clients.

FAQ

Get A Quote

We will contact you within one working day. Please pay attention to your email.